|

| June 17, 2014 | Volume 10 Issue 23 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

World Cup soccer ball design is engineering feat for adidas, Bayer MaterialScience

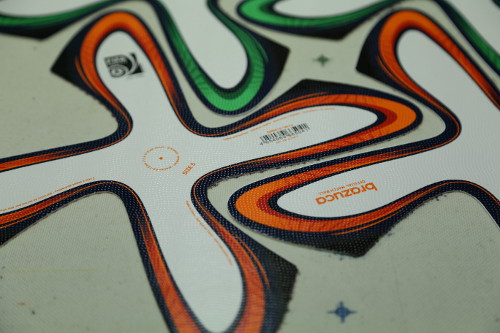

The most noticeable design element to the FIFA World Cup "Brazuca" soccer ball is its incredible surface piecing. Six identical star-shaped pieces make this high-tech ball a world-class example of great sports equipment engineering.

Although the 20th FIFA World Cup kickoff happened only last Thursday, the official match ball -- the "Brazuca" -- has been available for a couple of months. The soccer ball packs all the know-how and expertise gained in a nearly 30-year partnership between adidas and Bayer MaterialScience. The two companies have been working together in the field of ball development since 1986. From the outset, Bayer's polyurethane materials have played a key role, providing high-tech balls with their perfect shapes and outstanding properties.

The "Brazuca" reveals its true qualities on the pitch when precision passes are made or the ball flies true when shot toward the goal. This has been demonstrated not only in the sunshine, but also in very bad weather. More than 600 professional players and 30 teams in 10 countries tested the "Brazuca" under all kinds of outdoor conditions long before the World Cup started. Soccer greats such as Lionel Messi, Bastian Schweinsteiger, and Zinedine Zidane have already tested it. The ball was also used in friendly matches involving the German national team.

"This makes it the most tested ball that adidas has ever put on the market," says Oliver Bruggen, Director of Public Relations at adidas. The results of the laboratory trials also speak for themselves: The "Brazuca" complies with or exceeds all the standards set by the international governing body of soccer.

And that's all due to the ball's structure. Inside, it consists of an air-filled latex bladder. This is covered with a textile fabric that serves as a substrate for the outer layers. "But, in actual fact, the Brazuca owes its many highly praised properties to its outer skin," says Thomas Michaelis, project manager for ball development at Bayer MaterialScience. "It comprises a total of five layers based on Impranil polyurethane raw materials." They ensure optimal ball contact and prevent any moisture absorption. They are also responsible for the fact that the shape and appearance of the ball are retained for a long period of time.

The innermost layer of the skin is an adhesion coating that connects the textile substrate to the layers above. On top of this is a polyurethane foam layer, roughly 1 mm thick, made up of millions of gas-filled microspheres. This foam is highly elastic so that the ball, after being deformed from being kicked, immediately returns to its spherical shape to ensure an optimal trajectory.

The outer skin comprises three compact layers of polyurethane with different thicknesses. These layers are responsible for the outstanding resistance to external influences and abrasion, and for the ball's high elasticity. They also help to preserve its unique appearance.

But the most noticeable design element to this ball is its surface piecing. Who would have guessed that it would be made of modified "cross-style" or "star" elements -- and no stitching? While the top layer of conventional soccer balls consists of 12, 16, or even 32 panels, the "Brazuca" is made up of only six panels of absolutely identical shape all glued to the ball's surface and to each other. The perfect symmetry is not only an outstanding geometric achievement, it also has major advantages: The more panels used to cover the surface, the more seams there are that could absorb moisture. Fewer elements mean that the ball is more durable and more resistant to the elements.

The panels are bonded together using patented thermobonding technology. The assemblers obtain optimal results under defined pressure and temperature conditions -- and with a special, heat-activated adhesive based on Bayer's Dispercoll U raw materials. All of the assembly takes place in the town of Sialkot, Pakistan.

Typically Brazilian

The name "Brazuca" is a direct expression of the Brazilian joie de vivre, as is the colorful design of the ball. Even the creation of the name is typical of the soccer-crazed nation: more than a million Brazilian fans voted on the name, and it was chosen with a clear majority of more than 70 percent. This is a first in the history of the world football association, which had previously chosen the name of the official match ball itself. The name "brazuca" is an informal local term which means "Brazilian," or to describe the Brazilian way of life.

You can take a look at how the ball is manufactured in the video below. Note all the hand work.

And even though the month-long World Cup event will not end until July 13, adidas is already developing the next official World Cup ball: the company's contract with FIFA has been extended to 2030.

Source: Bayer MaterialScience

Published June 2014

Rate this article

View our terms of use and privacy policy